Special purpose machines

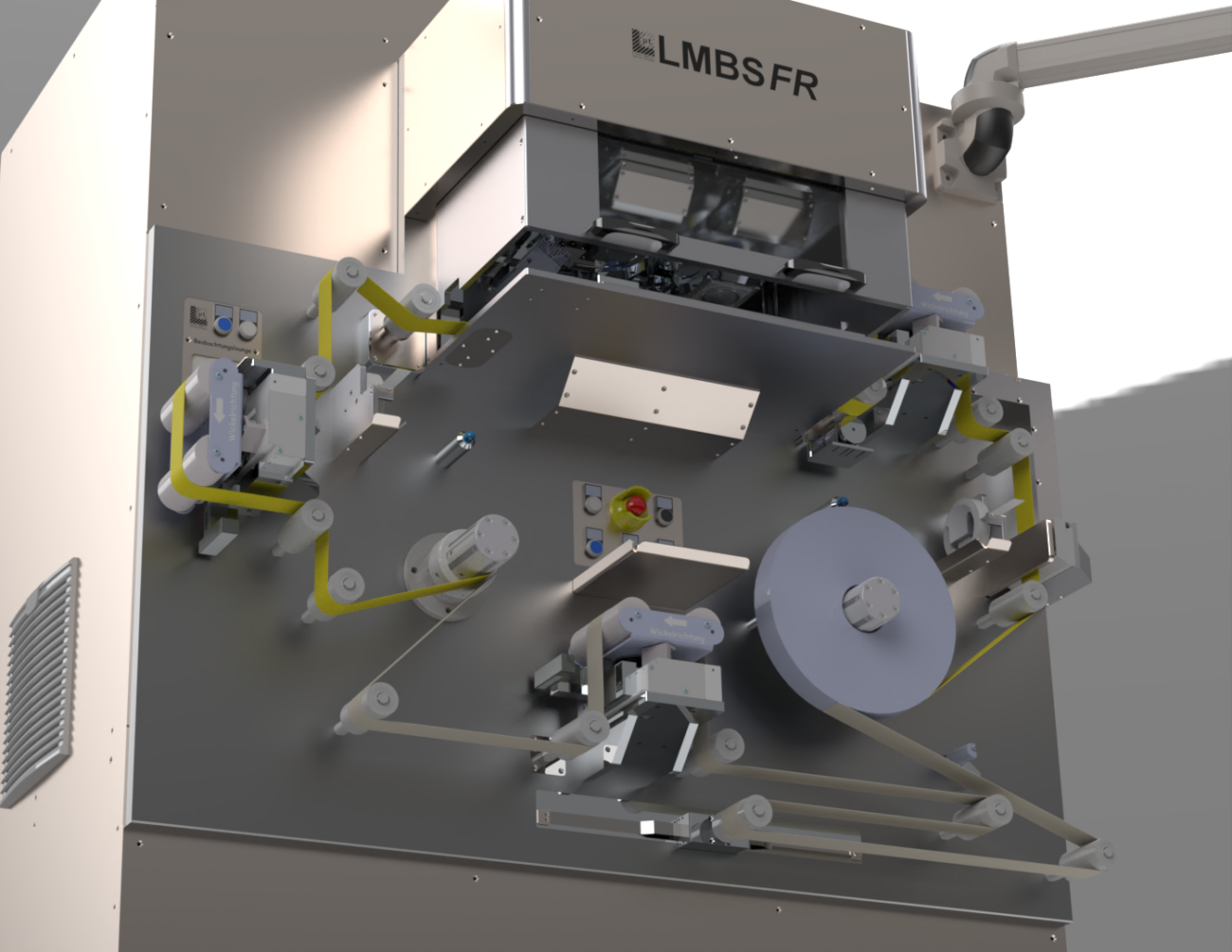

LMBS FR

The system enables the structuring of nitrocellulose membranes. This is a continuous roll-to-roll process. A characteristic feature of the system is that the structures are lasered onto the roll “on-the-fly”. The structures are then checked and evaluated using an integrated optical inline inspection system. The system was developed for use in clean rooms.

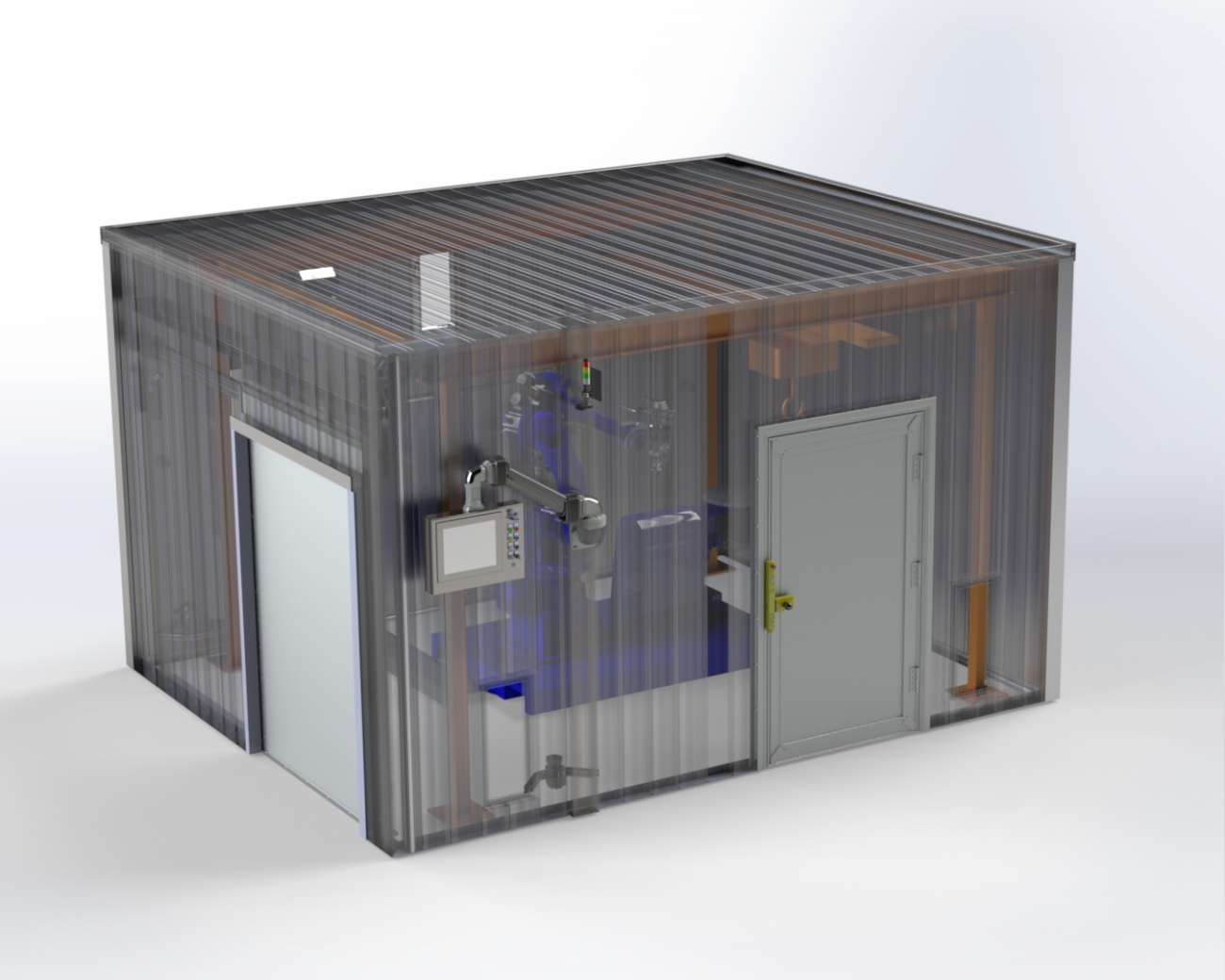

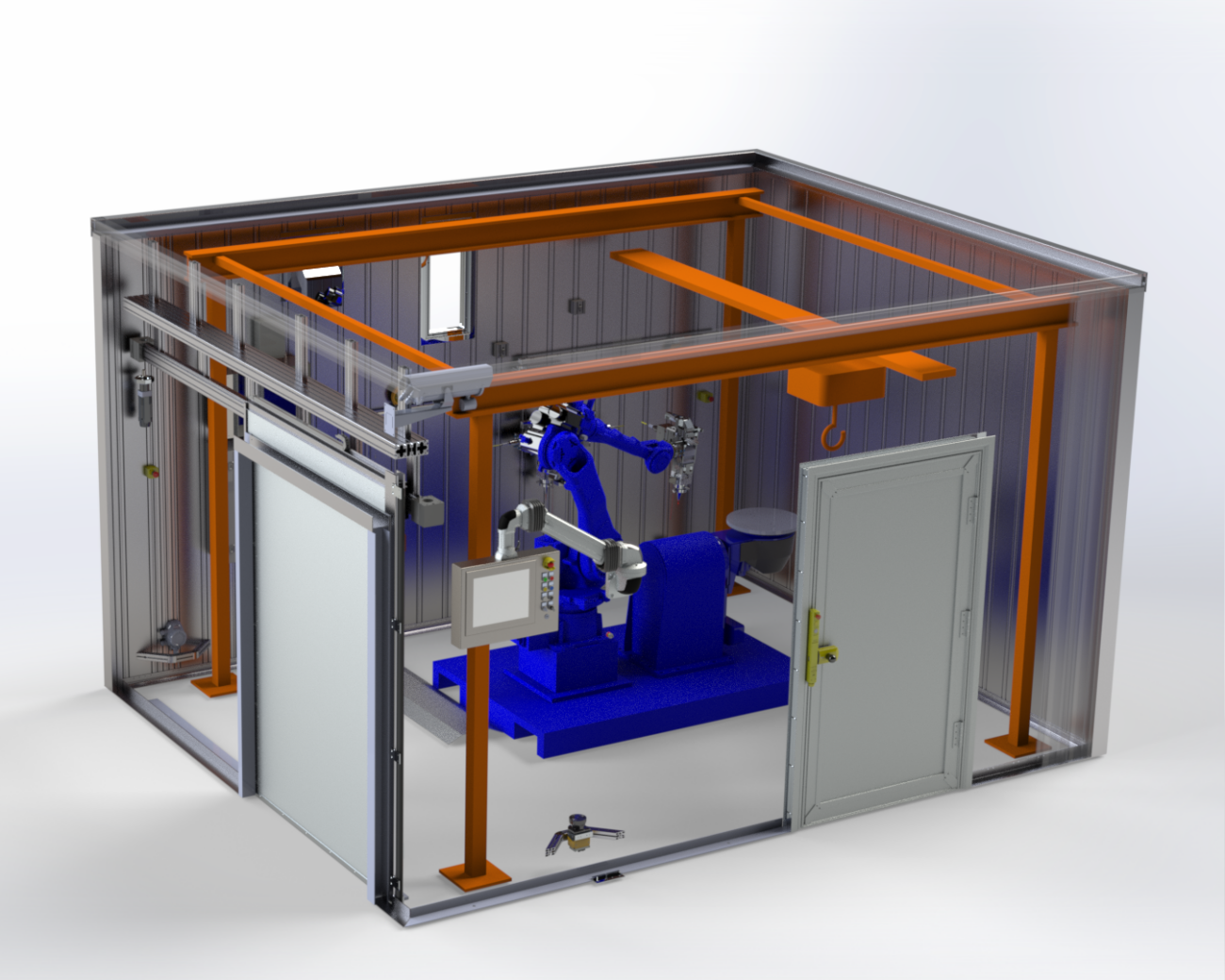

LTSS IR

The laser robot cutting and welding system is designed for automated, robot-assisted cutting and welding of various metal machine parts. The user can observe the entire process sequence via a camera.

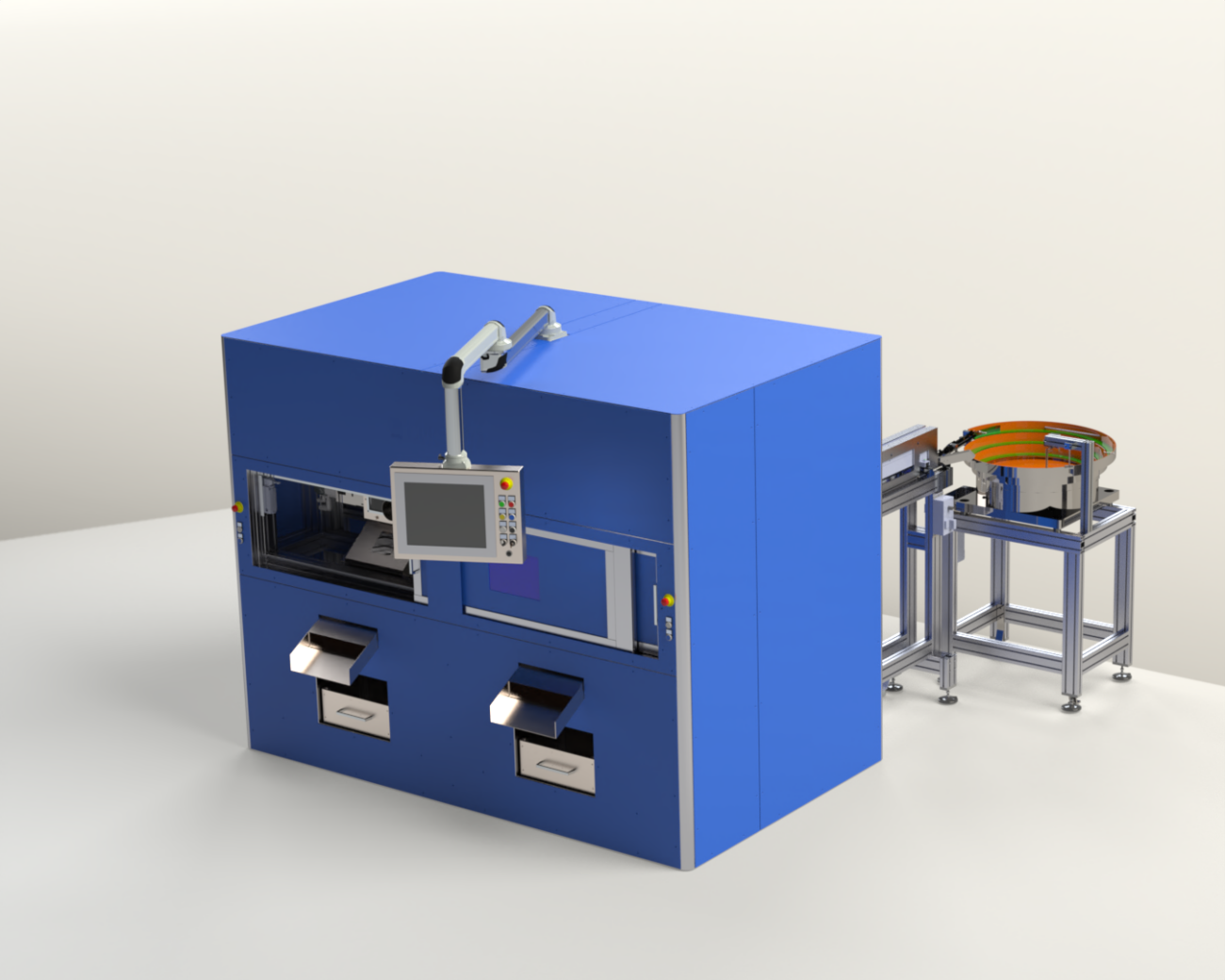

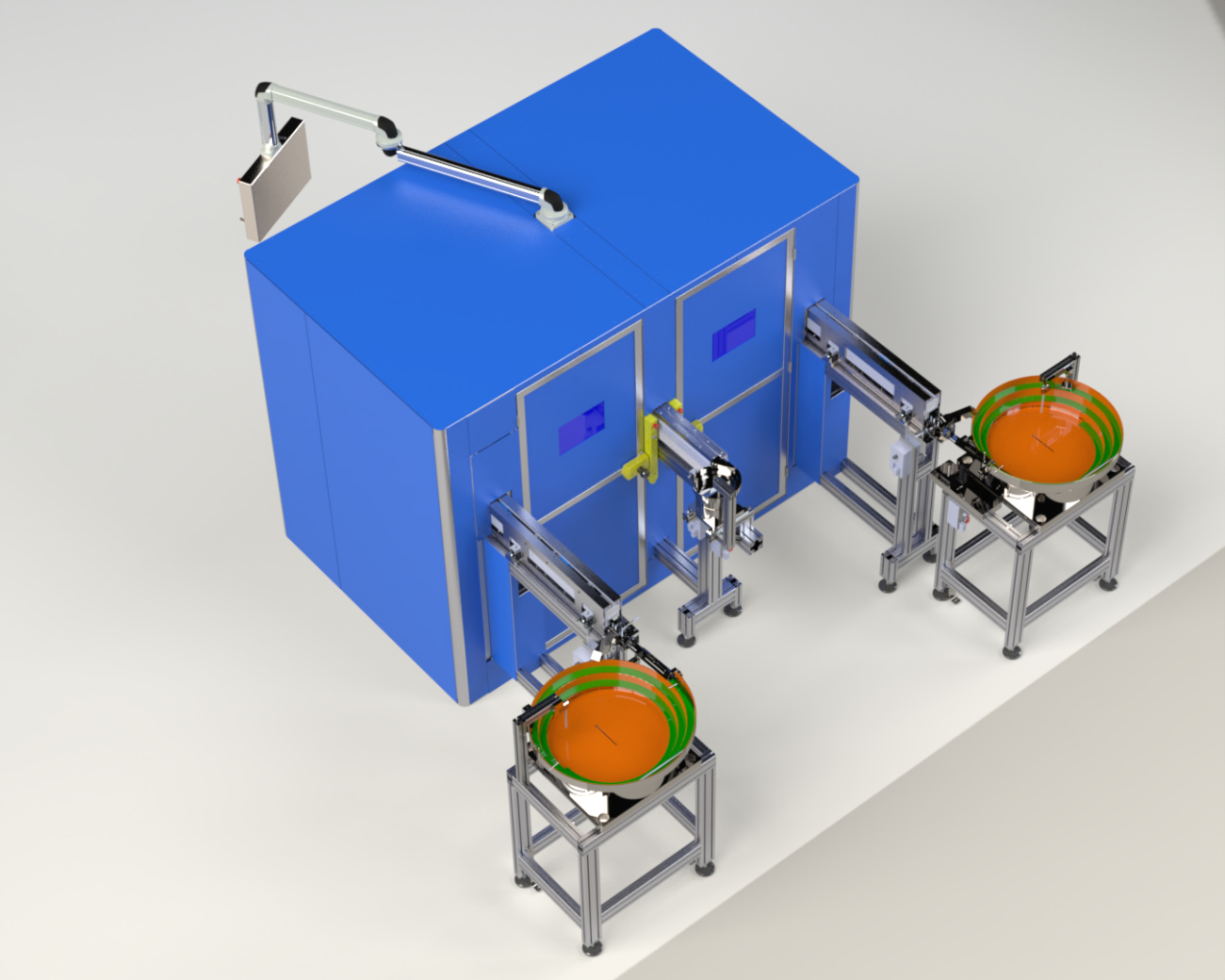

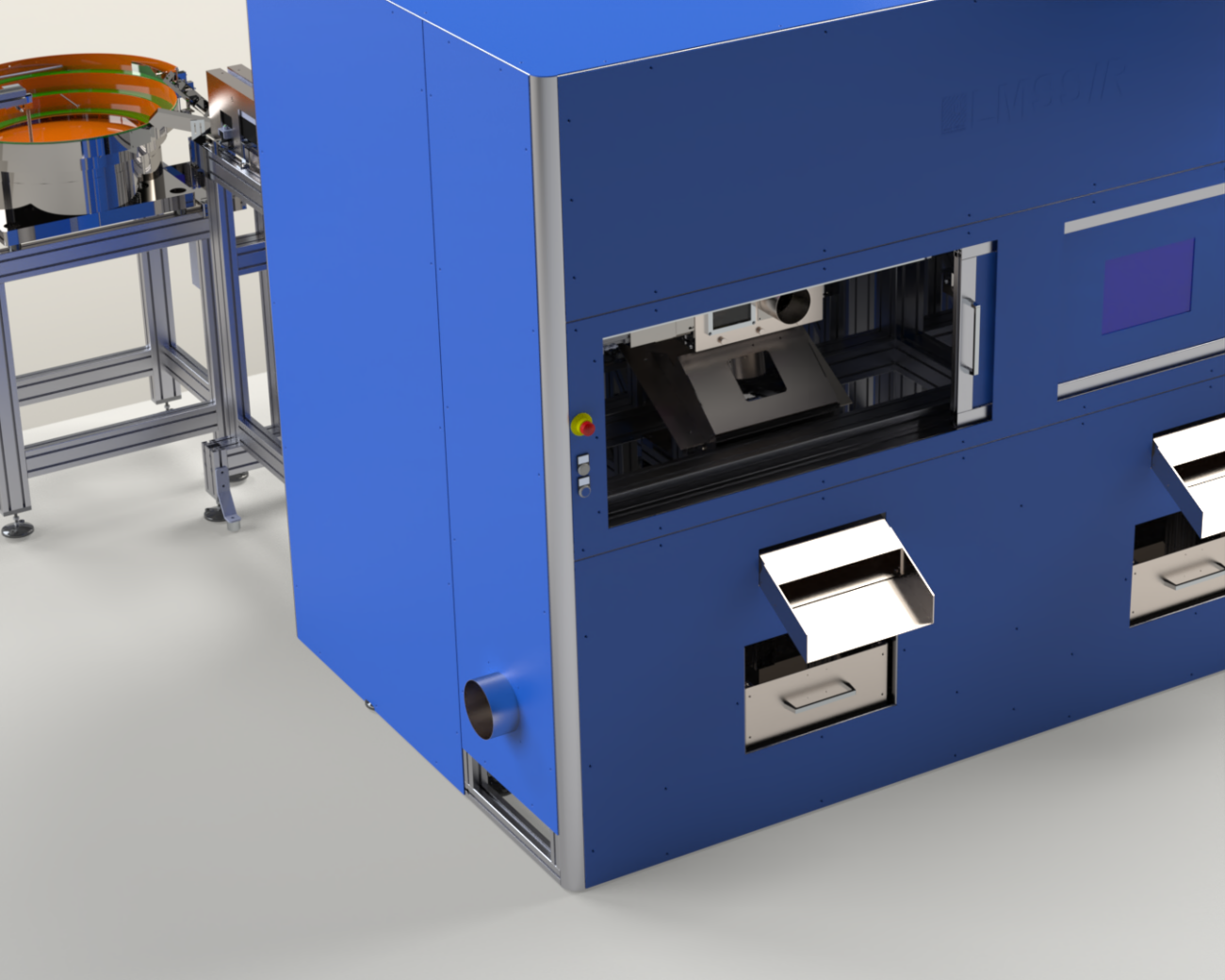

LMSS IR

The system has been specifically designed for laser beam welding of cylindrical solid metal rods. The parts to be welded are automatically transported into the system via vibratory spiral conveyors acting as buffers, where they are aligned and welded together. The entire welding process is monitored by cameras and subsequently analyzed. Based on this analysis, the finished parts are automatically sorted into containers for good and defective parts.

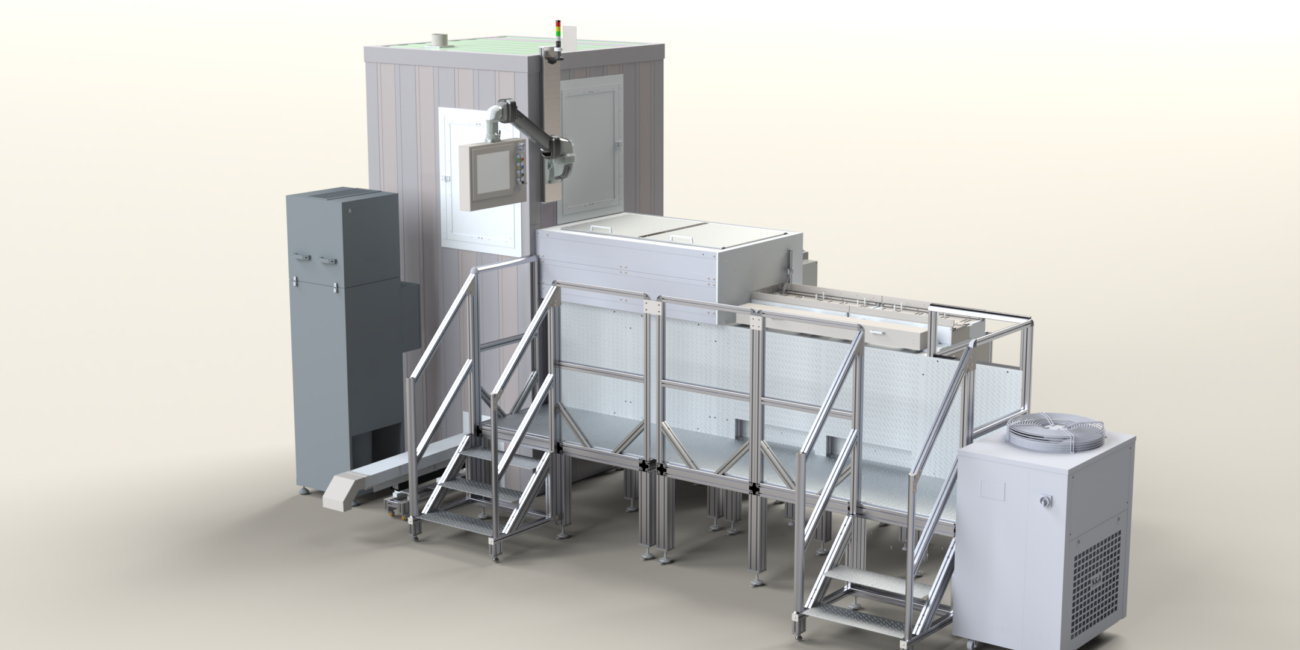

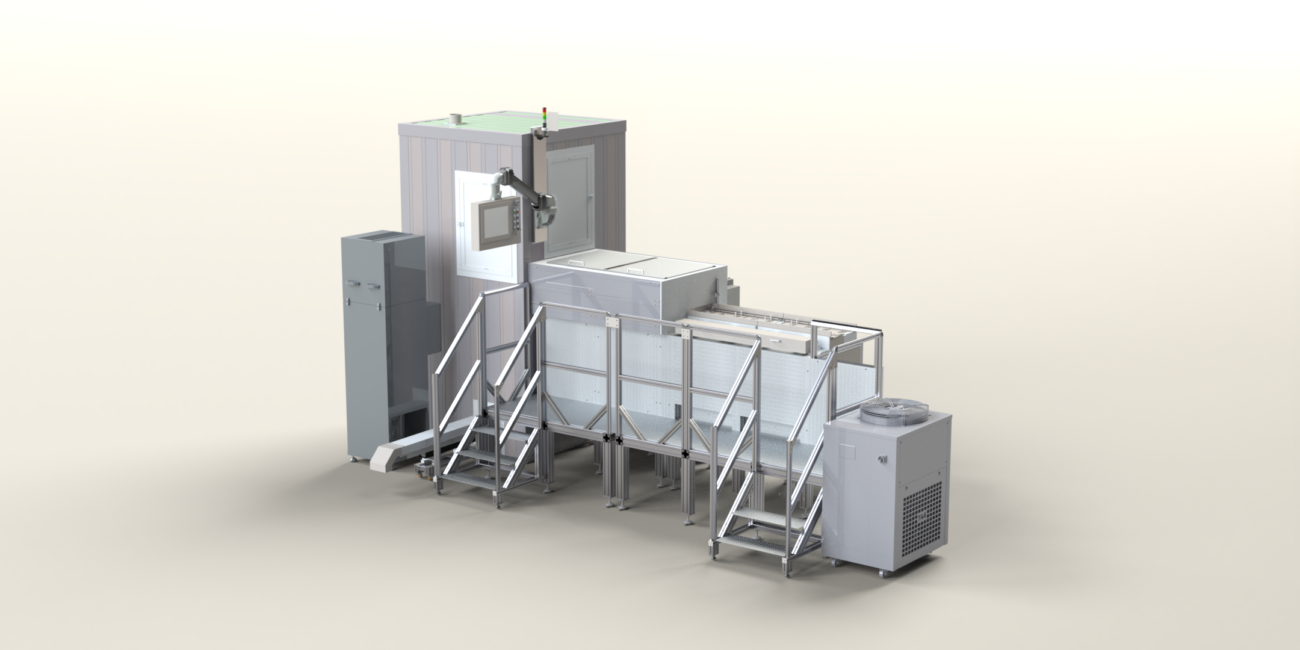

LMTS IR SC 4000

The laser system is fully automated and was specially developed for the precise cutting of metal foams. The system has been developed for industrial production. All components are water-cooled, which guarantees a reliable laser output of 4KW. The advanced camera monitoring with position control ensures maximum precision and quality. Thanks to laser class 1 certification, employees can work safely without the need for additional protective equipment.

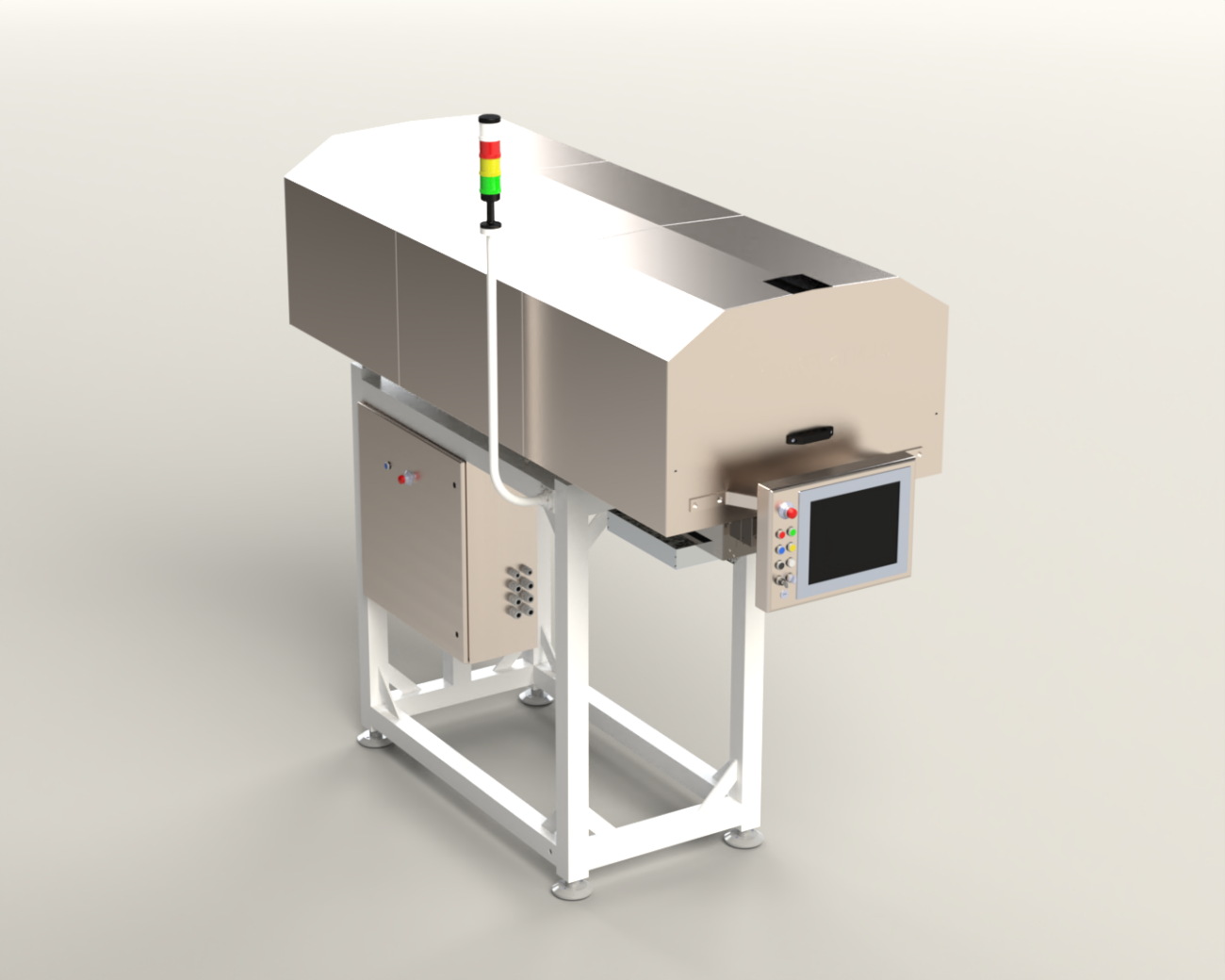

LMBS Fr quattro 2

The system enables ampoules to be separated. To separate the ampoules, the camera images are automatically analyzed to determine the correct locations. The system was developed for use in clean rooms.

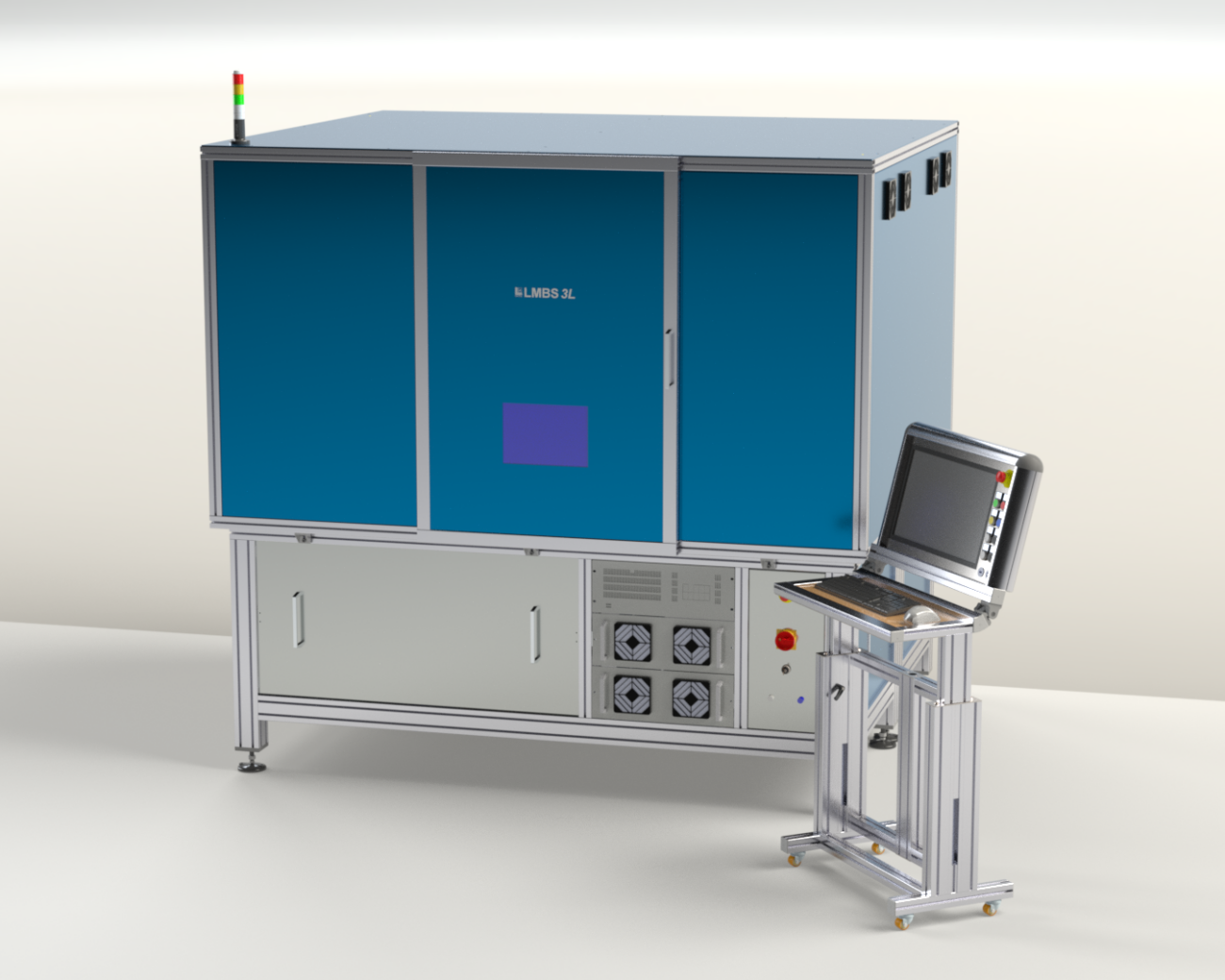

LMBS 3L

The laser system, designed for research facilities, impresses with its exceptional flexibility and versatility. Equipped with three laser sources (UV, IR and CO2), it is able to process a wide range of materials – from metals and plastics to cellulose and paper. With a total processing area of 550 x 550 x 200 mm (H/W/D) and a rotating and tilting device, the system offers sufficient space for various applications. An integrated camera not only enables monitoring of the laser results, but also subsequent evaluation and automatic adjustment via image recognition.